Italy returns to prominence in the field of long-range artillery thanks to the HITFIRE 155/52, the new turret developed by Leonardo, destined to become a central element of future terrestrial firepower within the company’s portfolio.

The project stems from the need to create a modern system, fully automated and fully integrated, capable of employing guided ammunition and operating according to the new multi-domain paradigms.

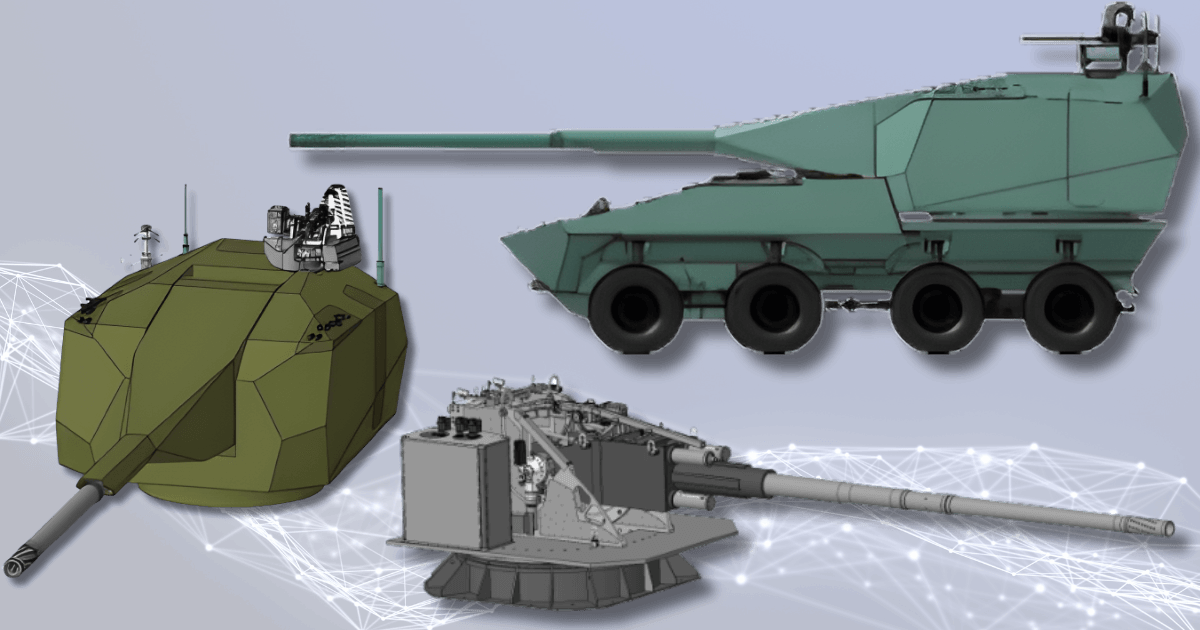

HITFIRE 155/52 is not merely the evolution of previous systems. The turret combines the 155/52 mm barrel developed in Italy, a redesigned automatic loader, and an electronic architecture aligned with new generation armored programs, from A2CS to NMBT.

The result is a system that aspires to position itself among the most advanced in the Western landscape.

A New 155/52 Cannon

The heart of the system is the 155/52 mm cannon, developed and manufactured by Leonardo in a version compliant with JBMoU (_Joint Ballistics Memorandum of Understanding_) standards: a 23-liter chromed chamber, right-handed rifling (48 lines) at constant pitch (20 calibers) and _”pepper-box”_ muzzle brake, a solution already tested on previous evolutions of national artillery, from the Palmaria to the M109L updated to 52 calibers.

The shell warehouse, located on the left, contains up to 30 projectiles, while the **launch charges, on the right, host 180**. Therefore, it is possible to fire all 30 projectiles in the magazine with the maximum allowable load, that is, six, to reach the maximum range.

Leonardo is today the only European industrial reality capable of independently producing barrels of any land and naval caliber, from 20 to 155 mm, with a production goal aiming to exceed 800 units per year. This places the company in a **unique position** in the new European industrial geography, increasingly oriented towards supply security and technological sovereignty.

Complete Automatic Loading

The automatic loader represents one of the most innovative elements of the project. Unlike previous systems, HITFIRE 155/52 uses two symmetrical loading arms, electrically operated, designed to operate at any angle of elevation (the maximum swinging is +70°) combined with a chain pusher. This is a solution entirely designed by Leonardo, which allows the grenade insertion sequence, charge positioning, shutter closing, and rearming to be fully automated.

It should be noted that Leonardo, strong with a long experience in designing artillery, has chosen a system that, in its precision and automation, remains as simple and reliable as possible.

The designers of the Italian company preferred to adopt mechanical nature solutions rather than just relying on a long chain of electronic sensors. This gives the system a designed robustness, allowing it, for example, to be able to shoot even with the vehicle in motion, increase the MTBF, and simplify maintenance.

The tests carried out at the UTTAT in Nettuno confirm the full functionality of the system. The technicians performed real sequences of fire, in which loading, closing, shooting, and casing ejection occurred without any human intervention.

Of course, the programmer for Spoletta Vulcano is present; Leonardo notes that, at the moment, the **HITFIRE is the only 155 mm artillery system that has been developed from the beginning for the use of Vulcano**.

Ballistic Performance and Advanced Capabilities

The combination of the barrel, loader, and electronic components allows HITFIRE to achieve notable performances. With **Base-Bleed ammunition, the range reaches 42 km**, while with the guided **Vulcano 155 family, it can exceed 70 km**, confirming full compatibility with the most advanced ammunition developed by the national industry.

The system can also execute MRSI shooting profiles (_Multiple Rounds Simultaneous Impact_), hitting a target with **multiple projectiles** simultaneously thanks to the automatic variation of angles and firing sequence.

The maximum cadence reaches **ten rounds per minute**, a high value for a platform mounted on a wheeled vehicle and made possible by the total automation of the loader.

C5I Integration and NGVA

One of the distinctive traits of the turret is its complete digitization. HITFIRE shares the same electronic philosophy of new Italian land programs, A2CS, NMBT, VBM-NG, and uses a C5I suite with full NGVA architecture (**_NATO Generic Vehicle Architecture_**).

It is also compatible with **JDIFSS** (_Joint Digital Indirect Fire Support System_), the multi-service network for indirect fire support. This feature opens the door to the possibility of engaging long-range targets by leveraging the contribution of sensors and platforms belonging to different domains.

Leonardo has tried in recent years to make the hardware part and the software framework of the systems installed on the vehicles common, and then modify them through the installation of “packages”

Close Defence

The design of the turret integrates the **30×113 mm HITROLE** as a C-UAS close defense element. This solution allows engaging drones, light threats, and opportunistic targets. The presence of C-UAS sensors, laser warning, smoke launchers, and an adequately calibered machine gun strengthens the overall protection of the vehicle, making HITFIRE a more resilient system to modern threats, especially in scenarios saturated with tactical UAVs and circulating ammunition, and giving it an adequate secondary capacity to engage ground targets when there is a tactical need; in fact, **HITFIRE can always perform direct fire with the main weapon.**

Installation On Wheeled Platforms

HITFIRE is designed to be installed on 10×10 trucks, 8×8 or 10×10 armored vehicles, and tracked vehicles. However, the main study involves integration on a new **wheelbase inspired by the VBM NG 8×8**, the latest VBM version. This configuration would maximize logistical commonality with the vehicles already in service and those soon to be introduced, adapt the hull to accommodate a **13-ton turret** and loading architecture.

The vehicle specifications speak of a **platform with a total mass under 35 tons**, anti-mine protection, **720 HP engine** (slightly enhanced compared to the original) and **a maximum speed of 110 km/h**, enough to guarantee high tactical mobility even on complex terrain. The only necessary modification is the lengthening of the frame in the middle, between the second and third axis, by about **420 millimeters** to allow a better weight down and to contain the kickback effort under 70 tons.

The vehicle will be equipped with protection that can be increased based on customer needs; furthermore, the VBM Plus-HITFIRE system will be able to perform all target data acquisition procedures and loading and **shooting on the move on 360° to respond to the most modern operational requirements of the “_shoot and scoot_”** to avoid counter-battery fire.

The crew/service team of the system is reduced to two people: **driver and vehicle commander**; both will be able to work with the main and secondary weapon system. Automation of the system eliminates, indeed, **the need for dedicated servers** for loading operations, while increasing the safety of the crew operating inside the armored vehicle and reducing operating costs.

Automatic Refuelling

Alongside the turret development, Leonardo is studying a fully automated reloading system using a logistical vehicle, equipped with a dedicated module, could transfer charges and grenades directly into the turret’s magazine **without any human personnel having to expose themselves to the operational environment.**

This is a solution designed for high-intensity scenarios, in which the speed of refueling and the survival of the vehicle become critical factors. Logistics automation represents **one of the elements of greater discontinuity compared to past systems, placing HITFIRE in a new operational category for Western armies.**

The company continues to develop both the operational vehicle and the logistical one but on the latter, although the “transfer” automatic system is being designed, **platform installation has not yet been selected.**

The 2025 Demonstrator

In 2025 Leonardo completed a demonstrator of the HITFIRE turret that resulted in a fully functional system. The shooting tests carried out at the **UTTAT in Nettuno validated the complete** loading, shooting, and recoil management cycle, providing the company with a solid basis for subsequent developments.

The entire process, including design, barrel construction, loader development, electrical integration, was completed **in about eighteen months**, an extremely fast timing for an artillery system of this complexity.

Leonardo expects to create **a prototype of HITFIRE by the summer of next year to end industrial qualifications by the end of 2026 or early 2027.**

Images: Leonardo